The footwear industry is undergoing a change and is currently moving towards the trend of mass customization, a process in which there is a resumption of the original era of artisanal production, but with the advantages of advanced systems and technologies that enable the production batch of personalized items, offering solutions that best fit the needs and desires of the consumer. It is known that, due to the great complexity of the structure of the feet and its dimensional diversity among the population, sneakers still present many ergonomic problems that cause damage that go beyond pain and discomfort and can lead to injuries and deformities in the feet.

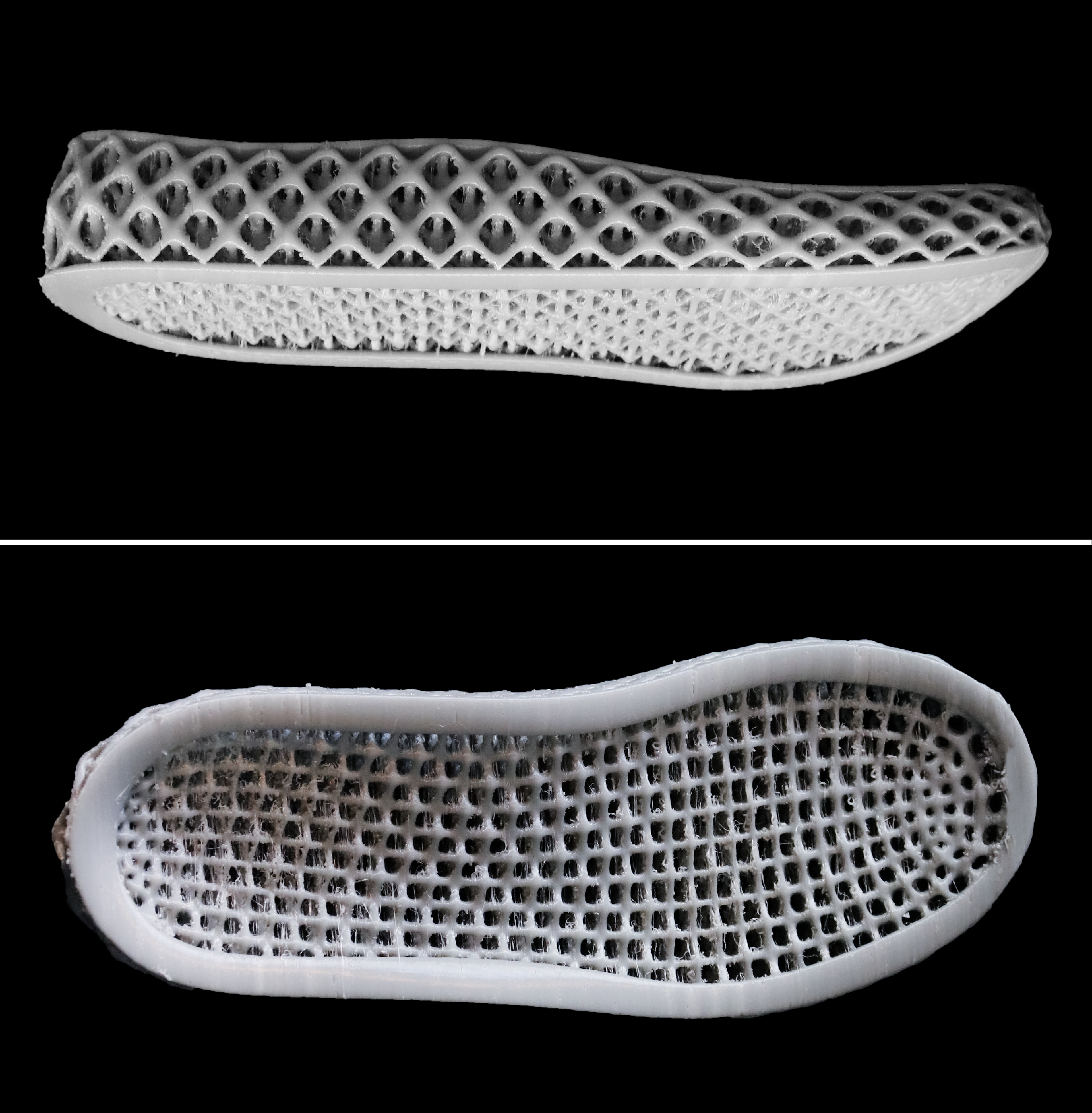

Based on this reflection, this project aimed to develop a proposal of customizable midsole based on algorithms and manufactured by 3D printing as a result of the combination of the concepts of mass customization, additive manufacturing and computational design. Through the construction of algorithm-based geometries, it was possible to create a midsole design capable of reacting to changes in its parameters according to anthropometric and foot pressure data. Thus, in addition to this Project contributing to the creation of a customized product according to the needs of each consumer, it also exposes the possibilities of using parametric modeling as a project tool in Industrial Design.

The foot is scanned to capture its measurements and shape, and foot pressure data is obtained through baropodometry. This information is processed by an algorithm developed in Grasshopper, generating a midsole with optimized mesh densities for impact absorption and comfort.

The midsoles were developed with four different lattice patterns. This image shows the first midsole design.

Second midsole design.

Third midsole design.

Fourth midsole design.

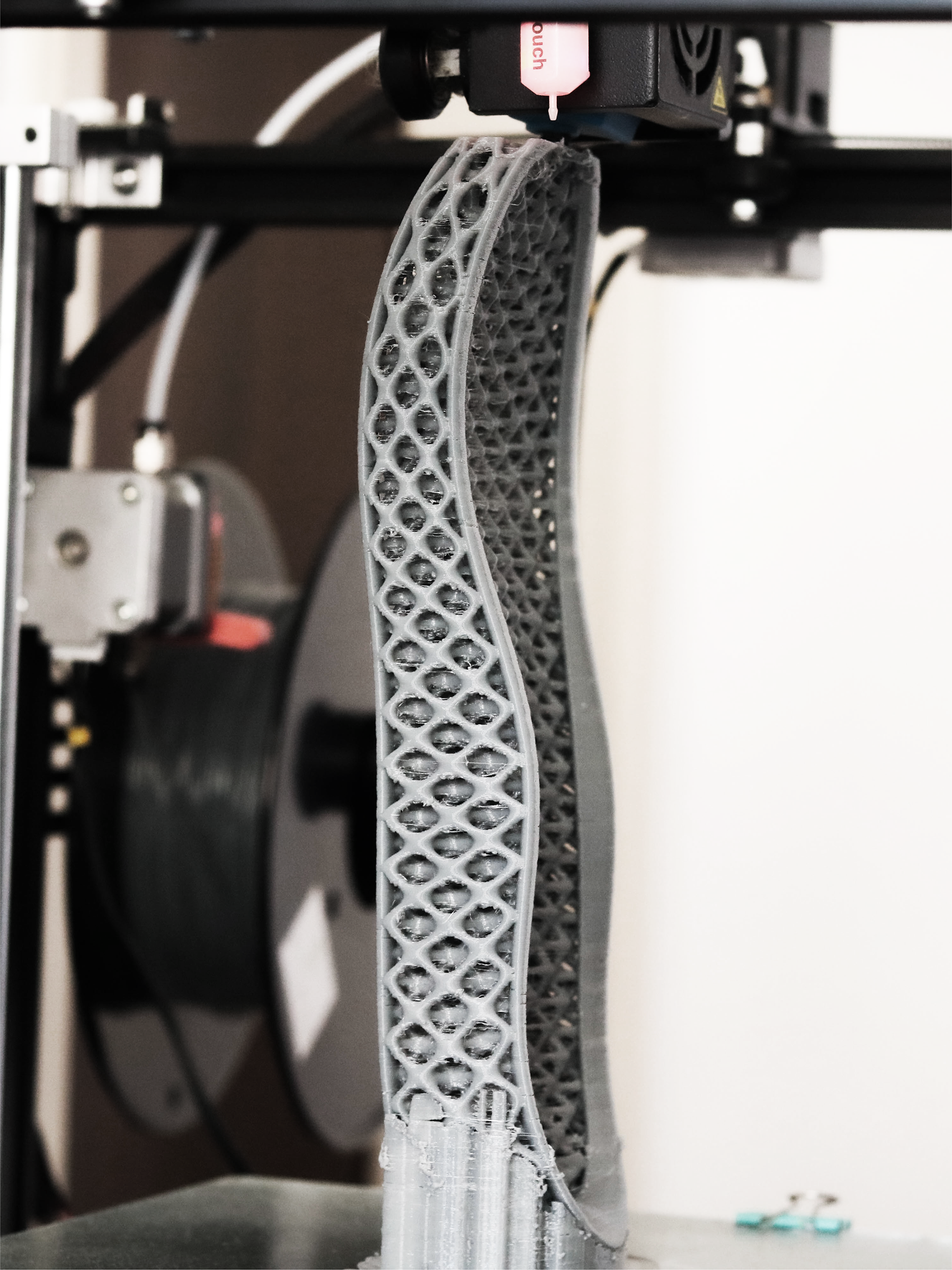

3D Printing Prototype in FDM, made with flexible TPU material

Access the article ,in Portuguese, based on the thesis, here.

Graduation Thesis

University: Federal University of Santa Catarina (UFSC)

Year: 2022

Design: Gabriela Chicarelli

Supervisor: Prof. PhD. Regiane Trevisan Pupo